When it comes to packaging products, choosing the right method is crucial to ensure protection, presentation, and cost-effectiveness. Among the various options available, shrink wrapping sealer is a popular choice for many businesses, but how does it compare to other packaging methods? In this article, we’ll explore the benefits and limitations of shrink-wrapping sealers and other common packaging techniques, helping you decide which one is best suited for your product.

What is a Shrink Wrapping Sealer?

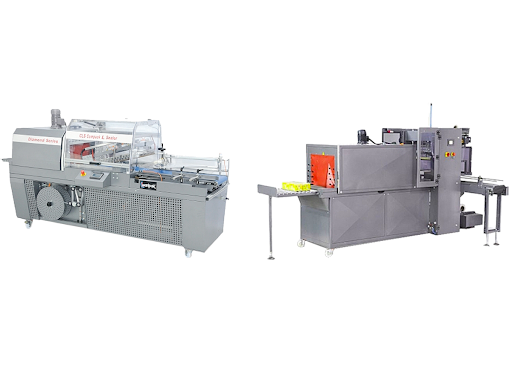

A shrink-wrapping sealer is a machine used to apply shrink wrap to a product. The process involves wrapping a plastic film around the item and then using heat to shrink the film, creating a tight, protective seal. This method is commonly used for packaging products like food, electronics, and consumer goods. Heat shrink tunnel systems are often used in conjunction with shrink-wrapping sealers to speed up the process by applying heat uniformly to shrink the film around the product.

Limitations of Using a Shrink Wrapping Sealer

- Environmental Impact: The plastic used in shrink wrapping is not always recyclable, which can be a concern for businesses looking to adopt more sustainable practices.

- Limited Aesthetic Appeal: While functional, shrink wrapping may not be as visually appealing as other packaging methods, especially for premium products.

- Not Suitable for Fragile Items: Shrink wrap may not provide adequate protection for delicate or fragile items, as it offers limited cushioning.

Other Packaging Methods

While shrink-wrapping sealer is a popular choice, there are other packaging methods that may be better suited for certain products. Let’s take a look at some of the alternatives.

1. Blister Packaging

Blister packaging involves sealing a product in a plastic cavity, often made of PVC or PET, which is then attached to a cardboard backing. This method is commonly used for small consumer goods like electronics, toys, and pharmaceuticals.

Benefits of Blister Packaging

- Product Visibility: Blister packaging allows customers to see the product inside, making it ideal for retail environments.

- Security: The sealed packaging provides protection against tampering, while the hard plastic offers more protection than shrink wrap.

- Customization: Blister packaging can be molded to fit the exact shape of the product, providing a tailored fit.

Limitations of Blister Packaging

- Higher Cost: Blister packaging tends to be more expensive than shrink wrapping, especially for low-volume production.

- Limited Product Range: This method is best suited for small, solid products and may not be suitable for larger or irregularly shaped items.

2. Box Packaging

Box packaging is one of the most common methods used for shipping and retail packaging. It involves placing the product inside a cardboard box, often with additional padding or inserts for protection.

Benefits of Box Packaging

- Protection: Cardboard boxes provide excellent protection for products, especially when combined with cushioning materials like foam or bubble wrap.

- Customization: Boxes can be printed with logos, product information, and branding, making them a good choice for businesses looking to create a professional image.

- Sustainability: Cardboard is often recyclable, making it a more environmentally friendly option compared to shrink wrap.

Limitations of Box Packaging

- Higher Cost: Box packaging can be more expensive, particularly when additional materials like padding or inserts are used.

- Space: Boxes take up more storage space than shrink-wrapped products, which can be a concern for businesses with limited storage capacity.

3. Pouch Packaging

Pouch packaging involves sealing a product inside a flexible pouch, typically made of plastic, foil, or paper. This method is commonly used for food, snacks, and liquids.

Benefits of Pouch Packaging

- Space-Efficient: Pouches are lightweight and take up less space than boxes, making them ideal for compact storage and transport.

- Customization: Pouches can be printed with eye-catching designs and branding, offering a more aesthetically pleasing option compared to shrink wrap.

- Versatility: Pouch packaging is suitable for a wide range of products, including liquids, powders, and solids.

Limitations of Pouch Packaging

- Less Protection: While pouches offer a level of protection, they don’t provide the same level of security as blister or box packaging.

- Limited Use for Large Items: Pouch packaging is typically used for smaller items and may not be suitable for larger or bulkier products.

Shrink Wrapping Sealer vs. Other Packaging Methods: Which is Best for Your Product?

Choosing between a shrink-wrapping sealer and other packaging methods depends on your product, budget, and specific needs. Let’s break down the key factors to consider when making your decision.

1. Product Protection

If your product needs protection from dirt, moisture, or tampering, shrink shrink-wrapping sealer is an excellent option. However, if you’re packaging fragile or delicate items, you may want to consider box or blister packaging, as these methods provide more cushioning.

2. Aesthetic Appeal

For products that need to stand out on the shelf or in retail environments, blister or pouch packaging may be a better choice due to their more visually appealing designs. Shrink wrapping sealer, while functional, may not offer the same level of presentation.

3. Budget and Volume

If you’re looking for a cost-effective packaging solution for high-volume production, shrink-wrapping sealer is often the best choice. It’s inexpensive and efficient, especially when paired with a heat shrink tunnel. However, for smaller production runs or premium products, you may want to consider blister or box packaging.

4. Sustainability

If sustainability is a key consideration, box or pouch packaging made from recyclable materials may be a better option than shrink wrap, which can have a higher environmental impact.

Conclusion

Both shrink-wrapping sealer and other packaging methods have their advantages and limitations, and the best choice depends on your product, budget, and priorities. Shrink-wrapping sealer is a cost-effective and efficient solution for many products, but if you need more protection, aesthetic appeal, or sustainability, other packaging methods like blister, box, or pouch packaging may be more suitable. Consider your specific needs and goals when selecting the right packaging method for your product.