When it comes to manufacturing body panels for vehicles, appliances, and industrial equipment, choosing the right material is crucial. One material that stands out for its strength, corrosion resistance, and longevity is Stainless steel coil 304. Widely used in the automotive and construction industries, this grade of stainless steel offers exceptional durability, making it the preferred choice for body panels that need to withstand harsh environments and mechanical stress. In this blog, we’ll explore why body panels made with stainless steel coil 304 are more durable and how they outperform other materials in terms of strength, longevity, and overall performance.

Understanding Stainless Steel Coil 304

Stainless steel coil 304 is a versatile and widely used grade of stainless steel that belongs to the 300 series. It is composed primarily of iron, with approximately 18% chromium and 8% nickel, which gives it excellent corrosion resistance, strength, and formability. The presence of chromium creates a protective oxide layer on the surface of the steel, preventing rust and corrosion even in harsh environments. This makes stainless steel coil 304 an ideal material for body panels that are exposed to moisture, chemicals, and temperature fluctuations.

Benefits of Using Stainless Steel Coil 304 in Body Panels

1. Exceptional Corrosion Resistance

One of the primary reasons stainless steel coil 304 is preferred for body panels is its outstanding corrosion resistance. The chromium content in stainless steel forms a thin, invisible oxide layer on the surface, which acts as a protective barrier against moisture, chemicals, and atmospheric elements. This ensures that body panels made from stainless steel coil 304 do not rust or corrode, even when exposed to rain, snow, or salt used on roads during winter.

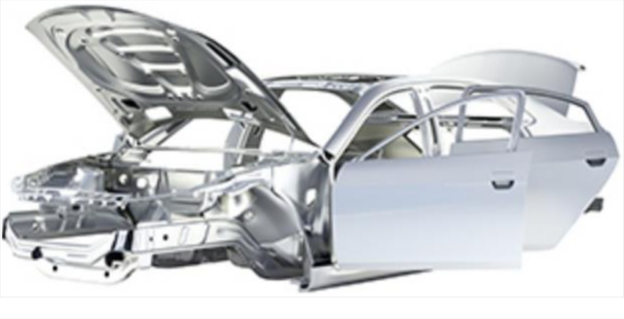

In the automotive industry, where vehicles are constantly exposed to harsh weather conditions and road salts, using corrosion-resistant materials like stainless steel coil 304 helps extend the lifespan of body panels and reduces maintenance costs. This makes it an excellent choice for manufacturing car doors, hoods, fenders, and chassis components.

2. High Strength and Structural Integrity

Stainless steel coil 304 is known for its high tensile strength and structural integrity. It can withstand significant mechanical stress without bending, cracking, or breaking, making it ideal for body panels that need to provide protection and support. Whether used in cars, trucks, or industrial machinery, stainless steel coil 304 ensures that body panels can endure impacts, vibrations, and pressure without compromising their performance.

For example, in the automotive industry, body panels made from stainless steel coil 304 provide added safety and protection to passengers by maintaining their structural integrity during collisions. Similarly, in construction and industrial applications, stainless steel panels are used to create durable enclosures, equipment casings, and architectural cladding that can withstand heavy loads and external forces.

3. Lightweight Yet Durable

While stainless steel coil 304 is strong and durable, it is also relatively lightweight compared to other metals with similar strength properties. This makes it an excellent choice for applications where weight reduction is essential, such as in the automotive and aerospace industries. Using lightweight body panels made from stainless steel coil 304 helps improve fuel efficiency and overall performance without compromising durability and safety.

In modern vehicles, reducing weight is a key factor in achieving better fuel economy and lower emissions. Stainless steel coil 304 allows manufacturers to design lightweight body panels that maintain high strength and impact resistance, contributing to both performance and sustainability.

4. Excellent Formability and Weldability

Stainless steel coil 304 is highly formable, allowing manufacturers to create complex shapes and designs without compromising its structural integrity. This makes it ideal for producing body panels with precise contours and smooth finishes. Additionally, stainless steel coil 304 can be easily welded using standard welding techniques, enabling seamless assembly and customization of body panels.

The ability to form and weld stainless steel coil 304 without losing its strength or corrosion resistance is particularly important in the automotive and construction industries. It allows manufacturers to create durable and aesthetically pleasing body panels that meet both functional and design requirements.

5. Long-Lasting Aesthetic Appeal

In addition to its strength and corrosion resistance, stainless steel coil 304 offers a sleek and modern appearance that enhances the aesthetic appeal of body panels. Its smooth, shiny surface is easy to clean and maintain, making it an attractive choice for both automotive and architectural applications. Unlike other materials that may fade, rust, or degrade over time, stainless steel coil 304 retains its appearance and performance for years, ensuring that body panels look as good as new even after prolonged use.

In architectural applications, stainless steel body panels are often used for building facades, interior cladding, and decorative elements, adding a touch of elegance and sophistication to modern structures. In the automotive industry, stainless steel trim and accents provide a premium look that appeals to consumers seeking both style and durability.

6. Resistance to Heat and Extreme Temperatures

Stainless steel coil 304 can withstand high temperatures without losing its strength or structural integrity. This makes it suitable for body panels that are exposed to heat, such as automotive engine compartments, exhaust systems, and industrial equipment enclosures. The material’s ability to maintain its performance under extreme temperatures ensures that body panels remain durable and reliable even in challenging environments.

For example, in automotive exhaust systems, stainless steel coil 304 is used to create heat shields and protective panels that prevent heat damage to surrounding components. In industrial settings, stainless steel panels are used to enclose machinery and equipment that generate high levels of heat, ensuring safe and efficient operation.

Applications of Stainless Steel Coil 304 in Body Panels

The versatility and durability of stainless steel coil 304 make it suitable for a wide range of applications, including:

- Automotive Industry: Car doors, hoods, fenders, chassis components, and exhaust systems.

- Construction Industry: Building facades, cladding, roofing panels, and structural elements.

- Industrial Equipment: Machinery enclosures, protective panels, and equipment casings.

- Appliances: Refrigerator doors, oven panels, and washing machine casings.

- Aerospace Industry: Lightweight body panels and structural components.

In each of these applications, stainless steel coil 304 provides the strength, corrosion resistance, and aesthetic appeal needed to ensure long-lasting performance and reliability.

Environmental Benefits of Stainless Steel Coil 304

In addition to its performance advantages, stainless steel coil 304 is also an environmentally friendly material. It is fully recyclable and can be reused without losing its properties, making it a sustainable choice for body panels. The long lifespan of stainless steel products reduces the need for frequent replacements, minimizing waste and conserving resources.

Many automotive and construction companies are increasingly using stainless steel coil 304 to meet sustainability goals and reduce their environmental impact. By choosing stainless steel body panels, manufacturers can create durable, energy-efficient products that contribute to a greener future.

Conclusion

Stainless steel coil 304 offers a unique combination of strength, corrosion resistance, lightweight design, and aesthetic appeal, making it the ideal material for body panels in a wide range of industries. Whether used in vehicles, buildings, appliances, or industrial equipment, stainless steel coil 304 ensures that body panels remain durable, reliable, and visually appealing for years to come. Its exceptional performance under harsh conditions, combined with its environmental benefits, makes it the preferred choice for manufacturers seeking to create high-quality, long-lasting products.

By choosing body panels made with stainless steel coil 304, you can enjoy the benefits of superior durability, reduced maintenance costs, and enhanced performance, making it a smart investment for both businesses and consumers alike.